Company

Sustainability at Winterhalter

As a warewashing specialist, we have been working to minimise the consumption values of our warewashers for over 75 years. Sustainability has long been ingrained at Winterhalter and is now a core value and a strategic corporate objective.

“We at Winterhalter have always considered sustainability to be an opportunity to help shape the future of our society. For us, sustainability means that our entrepreneurial approach is not only geared towards economic success, but that we also assume ecological and social responsibility. In our journey to achieving greater sustainability, we focus on transparency, traceability, feasibility and measurability – all while only making performance-based promises that we can keep.”

Ralph Winterhalter, CEO of the Winterhalter Group

Our five fields of action

Safe and ergonomic products

We support our customers in reducing the health and safety risks associated with using our machines and products.

Good working conditions

At Winterhalter, we foster a working environment that is equal, fair, positive and healthy – and fulfil our due diligence obligations in our supply chain.

Climate protection and energy efficiency

We are continuously reducing our negative impact on climate change in all business areas and produce energy-efficient warewashers.

Reducing water consumption

We are constantly working to minimise the amount of water required to produce and operate our products.

Supporting the circular economy

We offer highly recyclable warewashers and are continuously reducing waste in all business areas. This includes increasing the proportion of recycled materials.

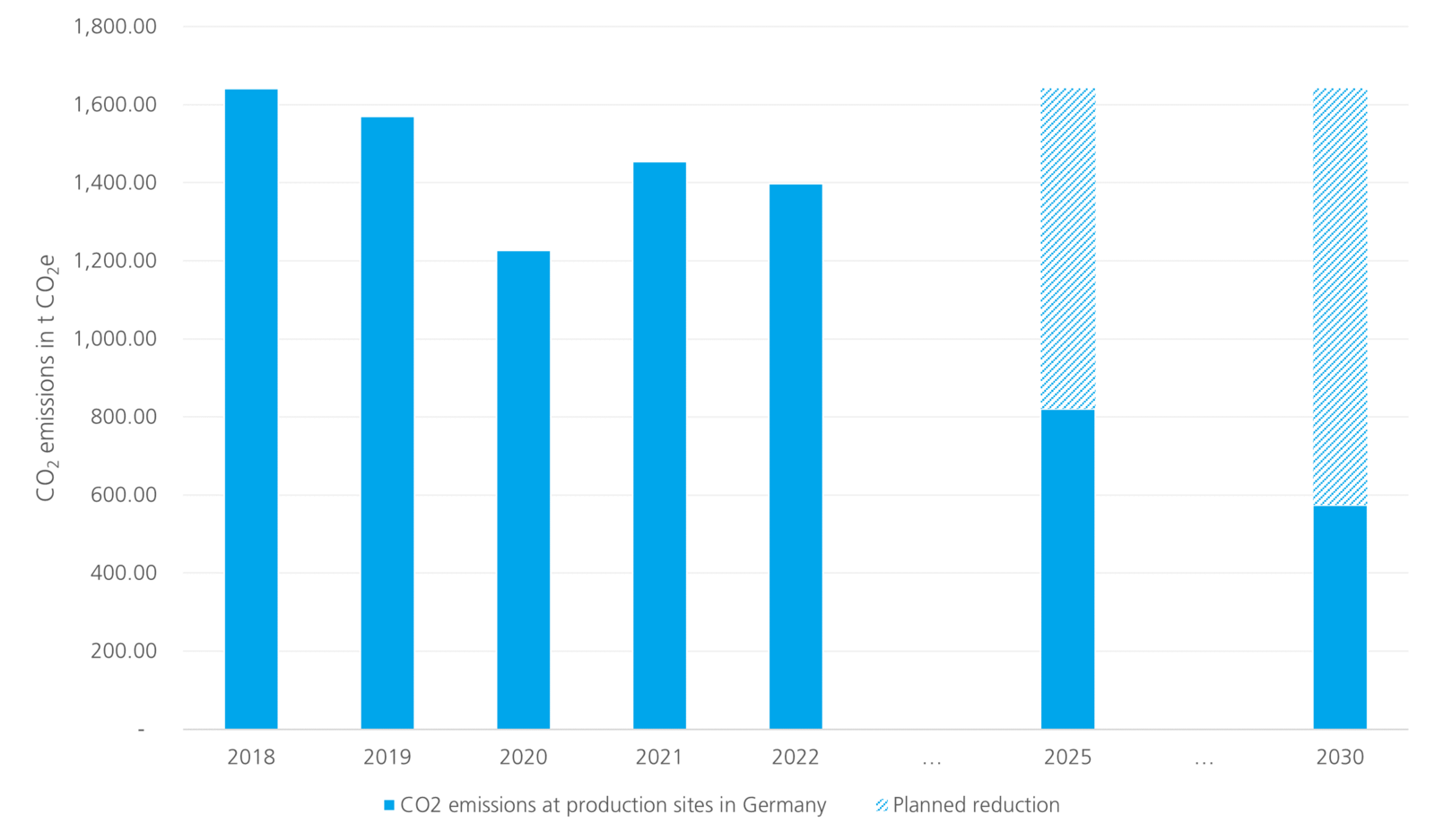

Our CO2 target

We aim to reduce the Scope 1 and 2 greenhouse gas emissions at our German production sites by 50% by 2025 and by 65% by 2030 – as compared to the base year of 2018.

“With our CO2 target, we are deliberately focusing on the reduction – and not the compensation – of greenhouse gases. From our perspective, the priority in combating climate change should be an absolute reduction of emissions. Effective and transparent offset projects can then serve as a last resort for unavoidable emissions.”

Debora Holder, Sustainability Manager at Winterhalter

Good to know: the different emission sources

A prerequisite for developing a climate protection strategy is to identify the company’s emission sources. In 1998 the Greenhouse Gas Protocol was developed with a view to creating an international standard for the calculation. Among other things, this includes the classification of a company’s greenhouse gas emissions into the three areas: Scope 1, 2 and 3.

SCOPE 1

This concerns an organisation’s direct greenhouse gas emissions. For example, the CO2 emissions from burning natural gas or heating oil to heat company premises. Or the use of petrol and diesel in company vehicles.

SCOPE 2

This category includes all indirect greenhouse gas emissionsthat occur while energy is generated, i.e. not within one’s own organisation, but rather by the energy suppliers. This applies, for example, to the purchase of electricity and district heating or the operation of electric vehicles.

SCOPE 3

Scope 3 includes all other indirect greenhouse gas emissionsassociated with the company’s activities that arise in the upstream or downstream value chain. For example, by purchasing stainless steel, using external transport companies or as a result of our customers operating the warewashers.

What we have already set in motion

Our warewashers are distinguished by numerous features –

not to mention their sustainability.

Resource conservation

due to low demand for water, energy and chemicals

High energy efficiency

through thermal insulation and heat recovery systems

Long service life

thanks to solid reliability and very good reparability

High occupational safety

due to simple, ergonomic and safe operation

Strong recycling potential

due to high stainless steel content and convenient disassembly