MTR

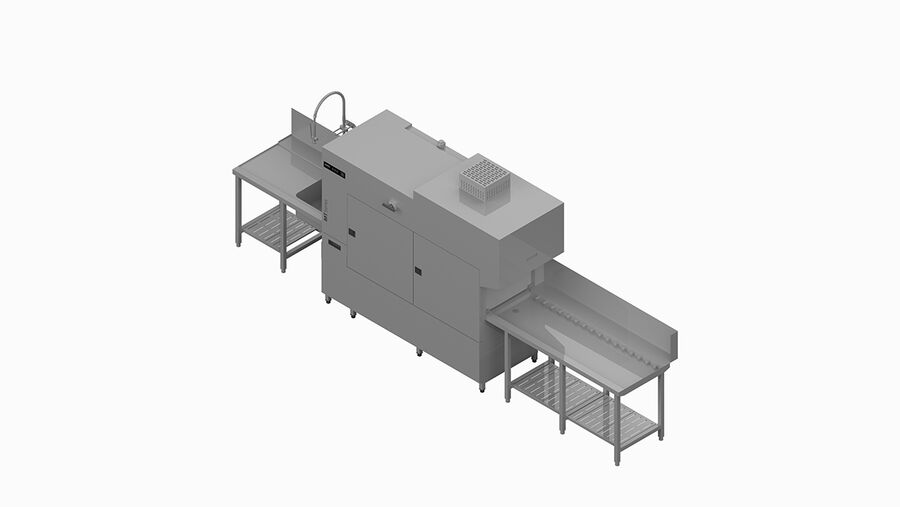

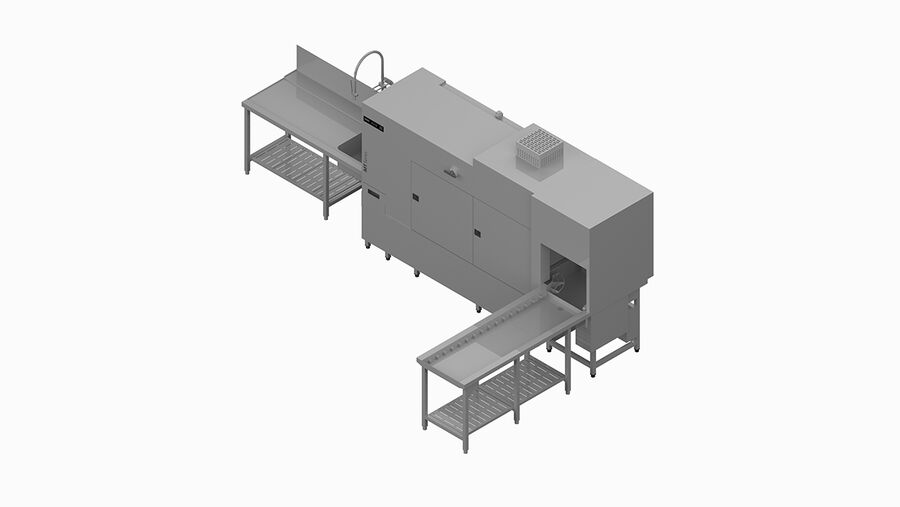

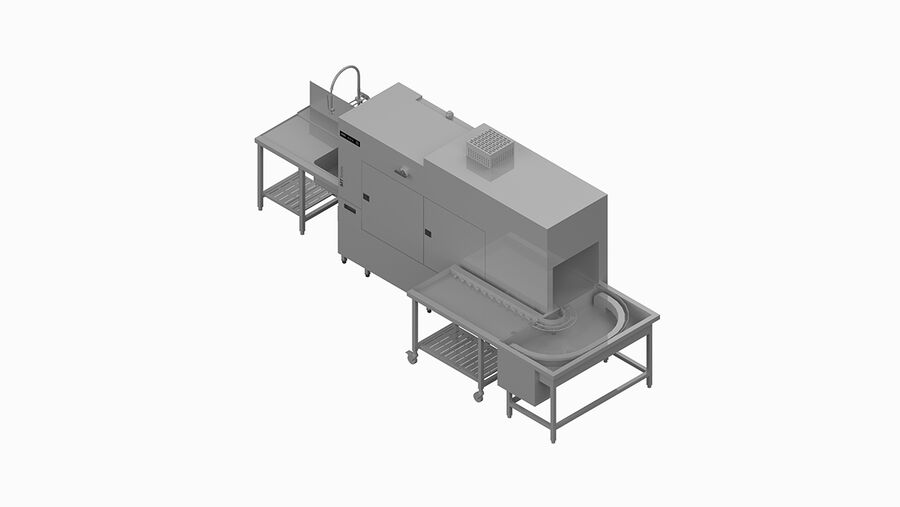

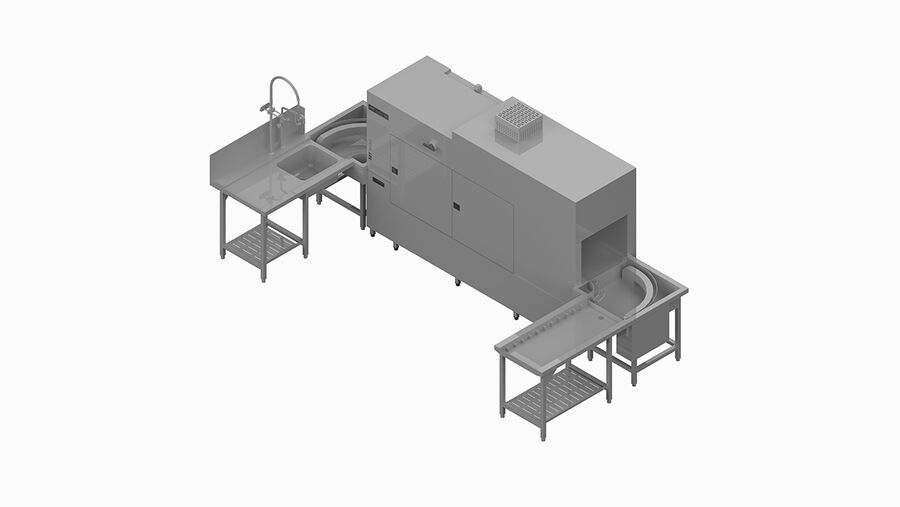

Rack conveyor dishwashers

Powerful performance. Modular system. The rack conveyor warewasher with a wide range of conversion and retrofitting options. For hygienic wash results and an economic washing process. And everything falls into place.

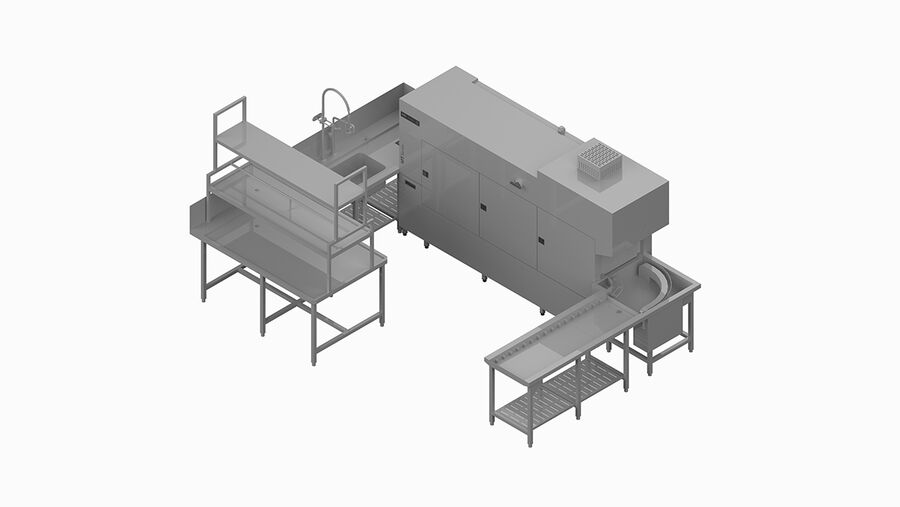

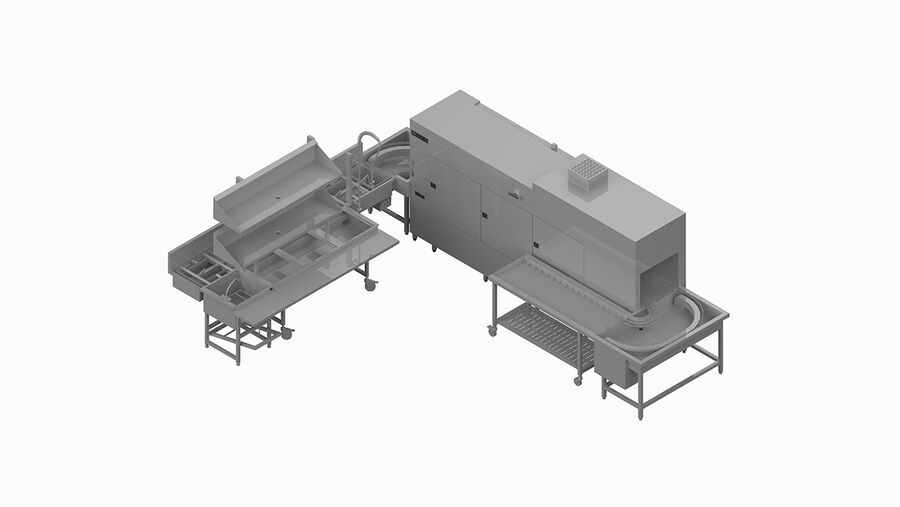

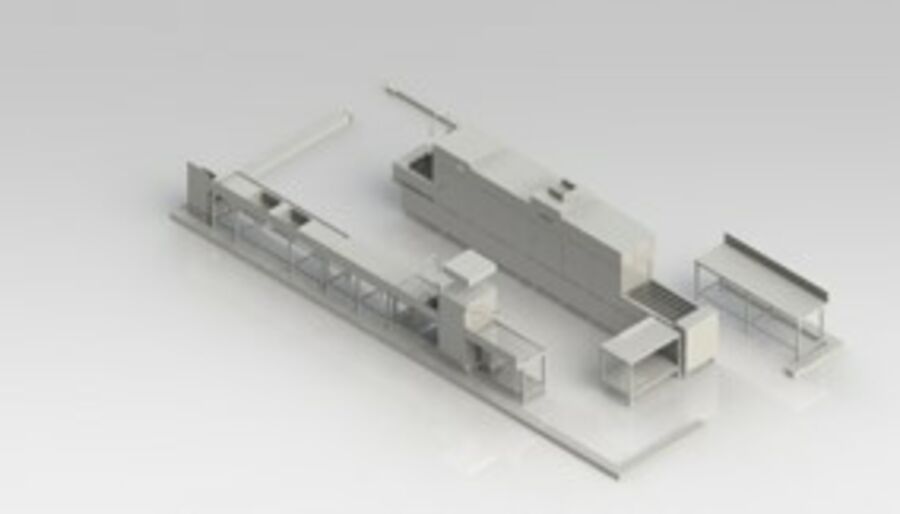

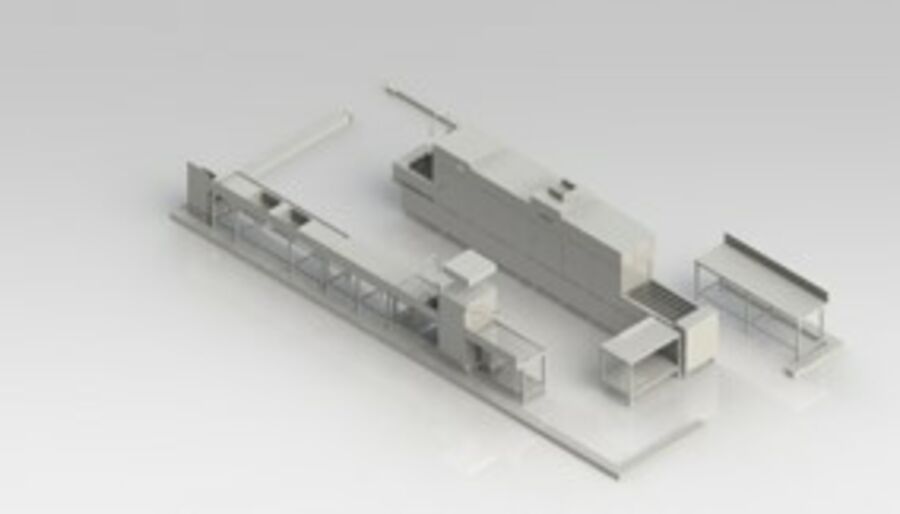

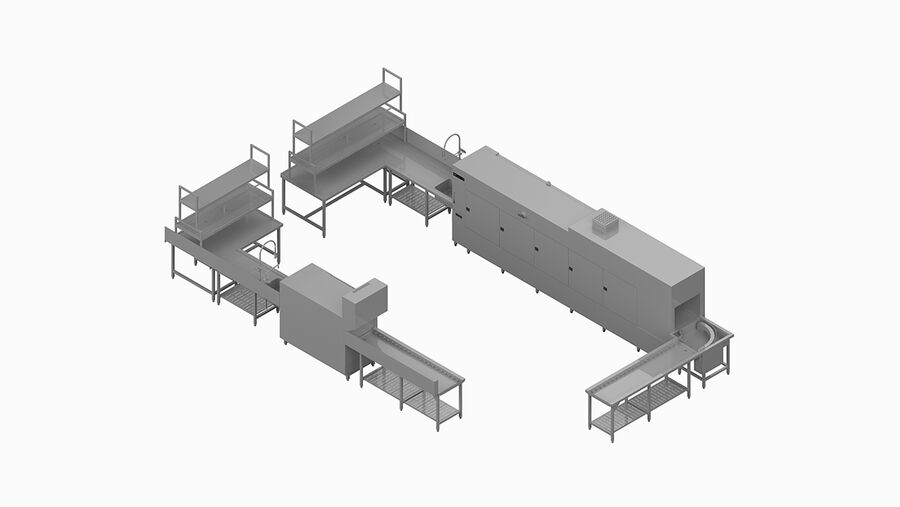

The dishwashing system for commercial kitchens

Peak times with up to 355 racks per hour. Filled with plates and cutlery, cups and glasses. And stacks of trays. And plenty of reusable cups and bowls in between. Different volumes of wash items distributed throughout the day – typical for restaurants and hotels, small and medium-sized canteens, hospitals and nursing facilities. Or service stations and caterers. In this area, the MTR series rack conveyor dishwashers set new standards: The machine architecture is based on a consistently well-designed modular system. This allows the machine to be customised to today's requirements more precisely than ever before. And: with the option of flexible retrofitting, it can also be adapted to the requirements of tomorrow. This means that the MTR adapts perfectly to every new situation and provides not only first-class washing performance but also maximum investment security.

Whether you have small or large wash items, and whether you are working at peak times or with a large amount of dirt: the powerful warewashing system and effective multi-filtration of the MTR series ensure consistently high wash results. Each zone helps to ensure first-class cleanliness and excellent drying. This ensures that your wash items come out of the machine spotless.

Washing is particularly economical with the MTR series. Water is used in a targeted and sparing way. Energy is used several times with the help of heat recovery. And if there is room for optimisation in the washing process, the machine gives proactive advice. All this provides efficient warewashing operation, saves resources and reduces your operating costs to a minimum.

The machine architecture and the hygiene and cleaning concept of the MTR series offer maximum hygiene safety. As standard, the machines meet the hygiene requirements of DIN EN 17735 and have the corresponding hygiene certificates. When in operation, the MTR monitors itself and automatically alerts you in the event of a hygiene-critical event.

When it comes to ease of operation, the MTR has set a new standard for rack conveyor dishwashers. The machine is intuitive and easy to operate. It is ergonomic, safe and time-saving. And it is very easy to clean. This means that the MTR provides the prerequisites for a fluid washing process with high reliability and fail-safe operation.

Complete flexibility. Maximum investment security.

Anyone who invests in a warewasher today wants to make the right decision for tomorrow. But what will the future bring? How much will the business expand? Will the environment change? Will new and innovative features be launched? With a MTR series rack conveyor dishwasher, you can relax and let these developments come to you. The machine architecture is based on a modular system and allows individual zones and components to be flexibly combined with each other. This has two big advantages. Firstly, the machine can be configured to perfectly match your needs and equipment requirements. And secondly, the machine can be converted or retrofitted at a later date. This means that the MTR series offers you the greatest possible security in planning and investment. To put it another way: when your business grows, the machine grows with it.

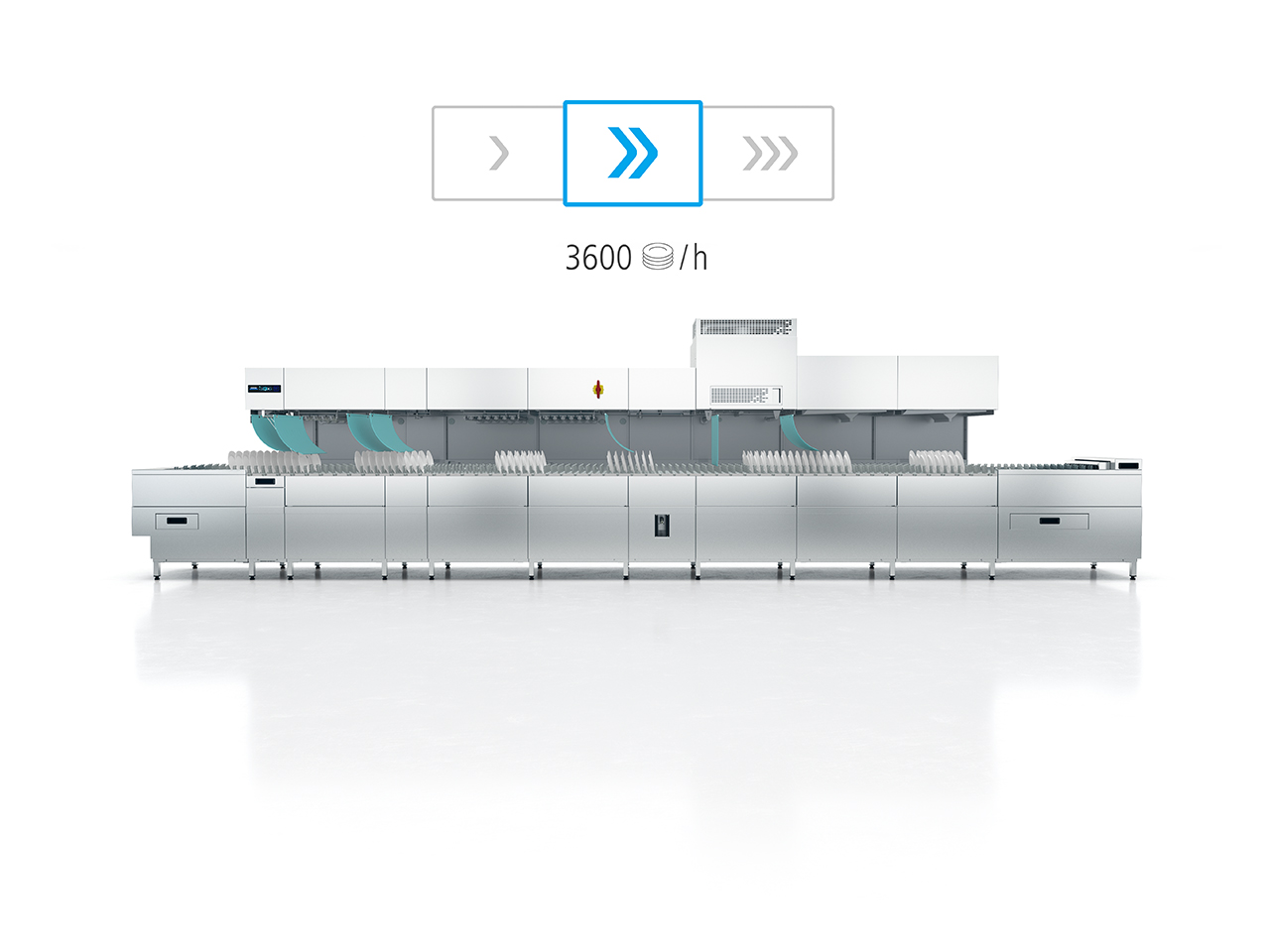

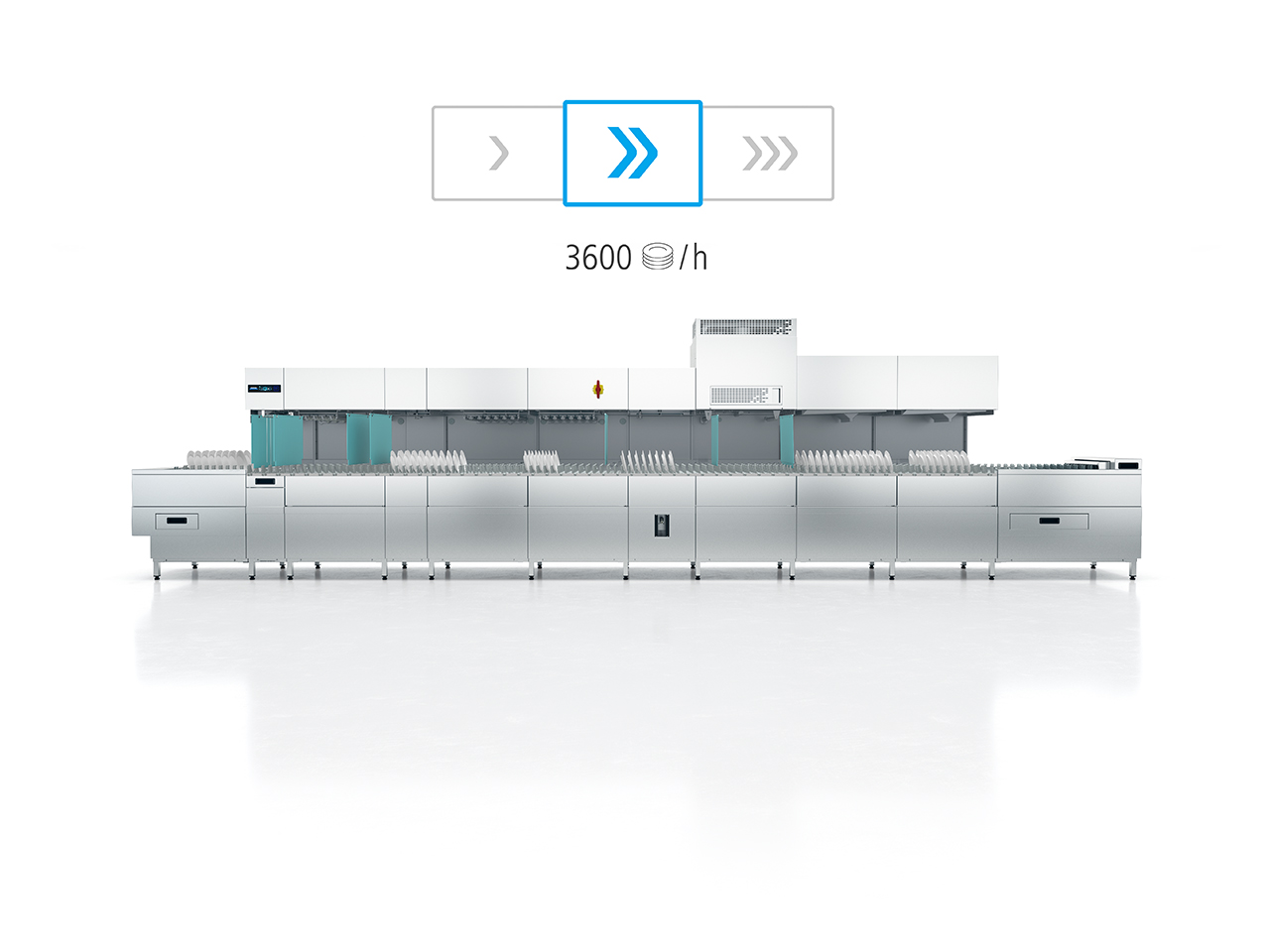

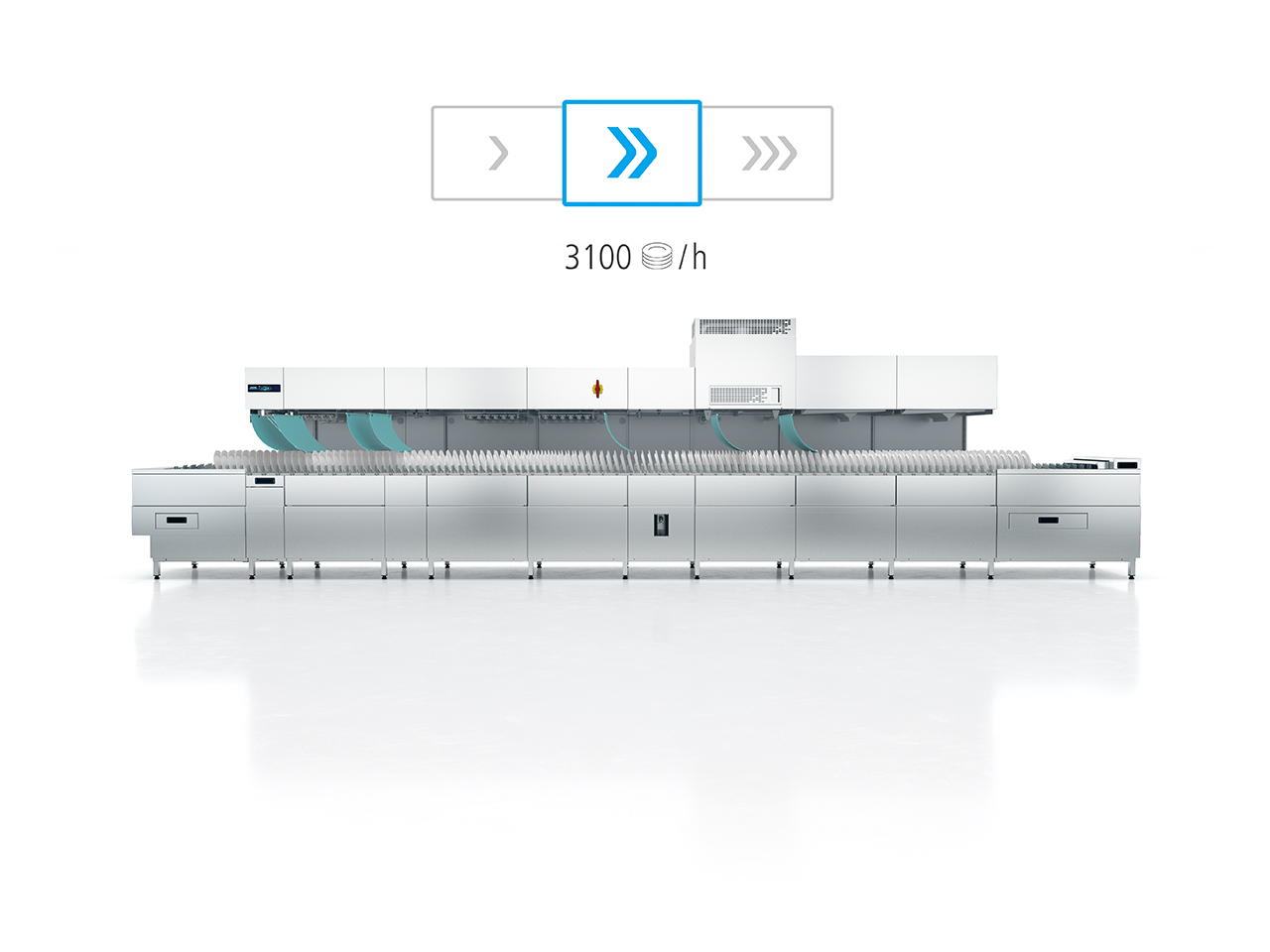

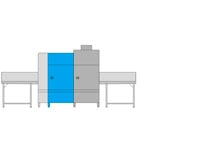

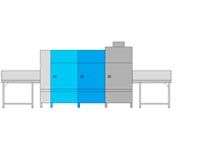

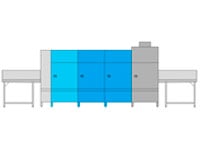

|  |  | |

| 2 tanks | 3 tanks | 4 tanks | |

|---|---|---|---|

Model

| MTR S | MTR M | MTR L |

Diners/h*

| approx. 200 | approx. 300 | approx. 400 |

Racks/h

| max. 190 | max. 275 | max. 355 |

*Deviations possible depending on operating mode and wash item volume

Product features

of the MTR rack conveyor dishwasher

Hygiene mode

Hygiene mode is a product feature only offered by Winterhalter conveyor dishwashers: If the tank or boiler temperature falls below the set value, the MTR automatically reduces its transport speed. This ensures full hygiene safety and DIN-compliant washing at all times.

Active dirt removal

In addition to the effective multi-filtration system, the MTR is also equipped with active dirt removal. It prevents coarse dirt from getting into the tank water in the first place and filters it out before the main wash cycle. The dirt is fed into the inlet zone and collected in the strainer drawer. This can be quickly and easily emptied during operation. This improves the wash result and reduces detergent consumption.

Triple rinse

The powerful triple rinse system of the MTR comprises an upstream rinse jet, the pumped rinse and the fresh water rinse. The rinse jet removes dirt particles and detergent from wash items before rinsing. In the process, the used water is fed back into the main wash zone. When combined with the downstream pump and fresh water rinse, the system ensures optimum wash results and minimum operating costs.

Rack-controlled zone activation

The MTR uses water, energy and rinsing chemicals in a targeted and economical manner. The individual zones for pre-wash, main wash and rinse are only activated when there are actually wash items in the respective zone. This conserves resources and minimises operating costs.

Speed-dependent rinse water volume

The MTR automatically adjusts the rinse water volume to the selected transport speed. At each stage, only as much rinse water is used as is actually required for a first-class wash result. Rinse aid is also dosed dynamically and adjusted to the rinse water volume. This provides for an economical washing process and saves resources.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

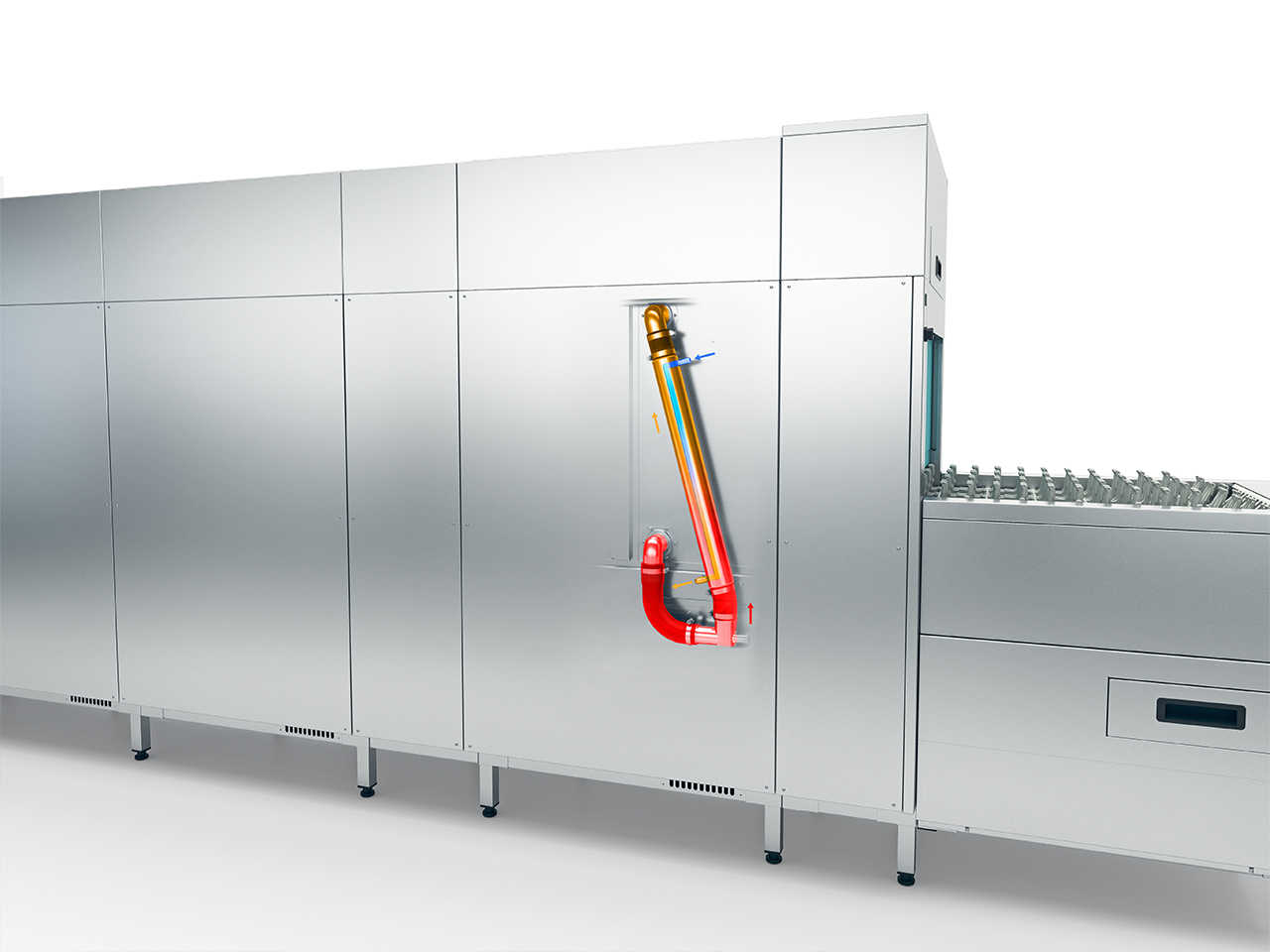

Pre-wash zone heat exchanger

Machines in the MTR series with at least three tanks are equipped with EnergyLight heat recovery in the pre-wash zone as standard. The stainless steel heat exchanger uses the hot water from the pre-wash zone to pre-heat cold inlet water. This recovers up to 2.5 kWh/h, which in combination with other features ensures a reduced connected load and savings in operating costs. The heat exchanger also regulates the water temperature in the pre-wash zone and keeps it at the optimum level.

USB interface

All operating data of the MTR can be accessed through the USB interface and stored externally as a hygiene report. This enables seamless compliance documentation of all hygiene standards according to HACCP. The service technician can also install updates via this interface. This keeps the MTR software up to date and newly added functions are immediately available. The USB interface makes this possible even if CONNECTED WASH cannot be used.

Heat recovery

Washing with the MTR makes optimum use of the energy input. The "EnergyPlus" heat recovery system uses the energy of the warm air to preheat cold inlet water in addition to the standard "EnergyLight" heat recovery system. The heat recovery has both a grease filter and an automatic self-cleaning function. Only steam that has already been released is used. This reduces the energy consumption of the machine, which lowers both the connected load and the operating costs.

Heat pump

The ClimatePlus heat pump uses not only the thermal energy of the escaping steam but also the energy from the room air to heat the MTR's tank and rinse water. The heat pump has a grease filter and an automatic self-cleaning function. The energy savings significantly reduce operating costs, the connected load is lowered and the room climate is improved.

FlexSpeed mode

The FlexSpeed mode automatically reduces the transport speed of the MTR if it is too high for the current working rhythm. This happens, for example, if the wash items are not cleared quickly enough from the machine outlet causing the washing process to be interrupted. Or, if large gaps occur when loading the machine. Adjusting the speed allows warewashing staff to work continuously. The FlexSpeed mode therefore ensures a smooth workflow and an efficient washing process.

Built-in solid dosing

The built-in solid dosing SPI (Solid Pump Internal) uses powder detergent. It is highly concentrated and about two thirds more efficient than a liquid detergent. The system is convenient, ergonomic and safe, as the cleaner cartridges can be replaced without any contact with chemicals. Further advantages of the built-in solid dosing include hygienic integration into the machine, space-saving storage of the replacement cartridges and the minimal volume of waste.

Integrated reverse osmosis

The integrated Reverse Osmosis Excellence-i removes up to 98 % of all minerals and salts from the water before washing. Activating the function switches the MTR to rinse with osmosis water and delivers wash results of the very highest level: glasses come out of the machine sparkling, cutlery gleams and shines – without the need for polishing. The Excellence-i water treatment system is fully integrated into the machine and does not require any additional space in the kitchen.

Smart Touch Display

The smart touch display is located on the infeed end of the MTR at an optimum working height: with single-button operation, language-neutral interface and self-explanatory pictograms. This makes the machine ergonomic, easy and safe to operate. The glass display is highly robust and sensitive and can be operated reliably even when wearing gloves. During washing, the machine constantly displays the current hygiene status in the form of a traffic light. The current temperatures of each individual zone can also be viewed. These and other functions can be accessed by the operator, chef and service technician on three operating levels.

Hygiene doors

The 180° swivelling hygienic doors give ergonomic access to the entire interior of the machine and allow easy and hygienic cleaning. This is where the big advantages over conventional lifting doors become apparent, because with the high-quality doors on the MTR series, the insides are also easily accessible and can be cleaned if necessary. The double-skinned doors are deep-drawn, acoustically and energetically insulated and a central component of the hygiene concept of the MTR.

For efficient and ergonomic washing

The more perfectly the work processes in the kitchen are organised, the more efficiently and ergonomically the warewashing staff can operate the machine. Therefore, there are custom-made accessories to match the MTR series for an optimal washing process.

Professionally planned. Neatly solved.

Clever spatial planning. Functional and energy-efficient technology. Economical operating processes and maximum hygiene safety. The demands placed on a professional commercial kitchen are high. The MTR series helps kitchen planners develop innovative operating concepts: with high-performance conveyor dishwashers that can be flexibly configured and perfectly matched to suit each customer's situation.